Shop owner Todd Blakney and the gang at Muscle Motors in Strathmore, Alberta, Canada had quite the challenge with this build. Their customer was looking for a period-correct-appearing Dodge 440 engine build to put into his 1971 Dodge Charger, but was looking for the most horsepower and torque possible from the engine. The end goal was to build substantial horsepower while retaining the street manners of the engine, and to that end, Ryan Brown Performance restored the Carter carburetor and Chrysler Electronic Ignition to like-new operation.

“We used a stock crankshaft and Six-Pack connecting rods, along with a set of Icon pistons making 10.0:1 compression,” Mike Breel of Muscle Motors tells EngineLabs. “Ryan Brown spec’d the Ultradyne custom hydraulic flat-tappet camshaft to help to take advantage of the stock intake and exhaust manifolds. The cylinder heads are 3462346 castings, and we used Ferrea 2.08 intake and 1.81-inch exhaust valves in them. Todd did a multi-angle valve job along with a bowl blend on the heads.”

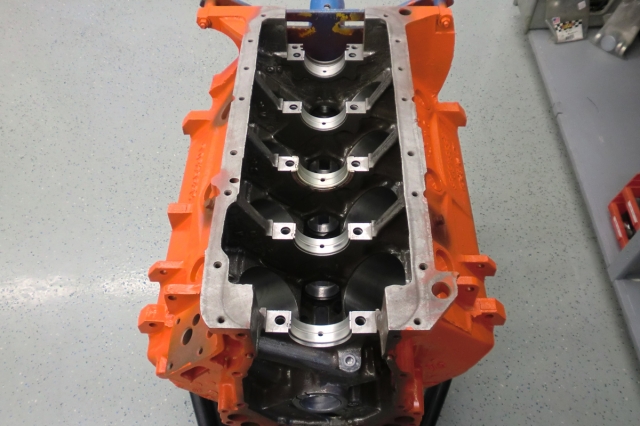

Cam specs check in at 231 degrees of duration at .050-inch on the intake side and 239 degrees on the exhaust side – lift figures are undisclosed. Block preparation and machining was completed on a CNC-controlled RMC four-axis V40 machining center. The V40 has a Block True blueprinting fixture that maintains the crank-to-camshaft relationship to ensure correct alignment during all machining operations.

Block work was done on an RMC V40 CNC machining center, and the camshaft was degreed in to Ryan Brown Performance's specifications to produce the maximum amount of horsepower.

The rotating assembly was balanced and the entire engine was blueprinted during the assembly process, which takes more time but assures the Muscle Motors team that the parts and pieces will work properly upon startup.

Muscle Motors is a full-service machine shop that is capable of rebuilding any engine from stock to performance, and even does industrial engine rebuilds. They also have an on-site full mechanical shop that handles builds form mild to wild – even frame-off restorations.

“This customer wanted to run stock manifolds, intake and carburetor. The manifolds are the limiting factor, and as a result there isn’t much sense in opening the heads and then putting on a restrictive intake. Ryan really pulls every last bit out of it with his cam selection, as you can see from the dyno results,” says Mike.

The package was maximized given the limitations set forth by the customer, and the end result is production of over 500 lb-ft of torque and 380-plus horsepower on the Ryan Brown Performance dyno. Sweet build!