Heidts Automotive Group is a leading provider for performance suspension and chassis component solutions catering to the hot rod and muscle car industries. The company was started more than 25 years ago and has since grown to occupy more than 50,000 square feet at its headquarters in Lake Zurich, Illinois.

Heidts Automotive Group is a leading provider for performance suspension and chassis component solutions catering to the hot rod and muscle car industries. The company was started more than 25 years ago and has since grown to occupy more than 50,000 square feet at its headquarters in Lake Zurich, Illinois.

“Heidts has built its business on engineering excellence, quality products, and fast friendly service.”

Here’s the skinny on why Heidts prides itself as an industry leader:

- Heidts ships most orders within 24 hours of placement – within 48 hours at the latest.

- They carry an extensive inventory and can even build custom parts for the customer – you call in with the dimensions, then boom, product is delivered.

- Heidts’ expansion of its HQ has allowed all tests and prototypes to be fitted on to their own fleet of hot rods and musclecars.

- Heidts regularly enters its modified vehicles into autocross and road course competitions in order to apply stress tests in real world situations.

Engineering excellence is at the forefront of production over at Heidts. Jim Shaw’s design vision along with the shop’s skill at rendering the schematics into tangible parts is a harmonious marriage of labor. Coupled with the extensive tests they run on their own gallery of vehicles, Heidts challenges competition through its integrity during production.

These are a few resources that allow Heidts to keep production up while still ensuring a top quality product:

- Plasma Cutter: All of Heidts’ crossmembers and brackets are cut with high definition plasma cutters. In-house production allows instant inventory fulfillment when demand increases.

- Polishing: Heidts does all of its own polishing in-house ensuring quality control of beautiful looking parts.

- Press Brake: Heidts bends all of their crossmembers, brackets, and other components in-house.

- Lathe: Two CNC lathes and a turret lathe are kept running to capacity day and night.

- Welding: Heidts operates 12 MIG and TIG stations.

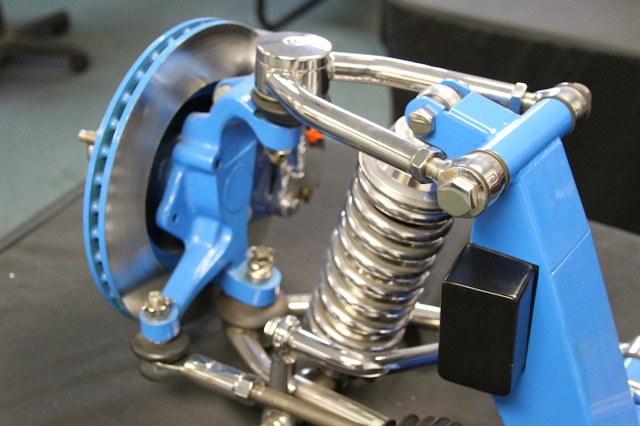

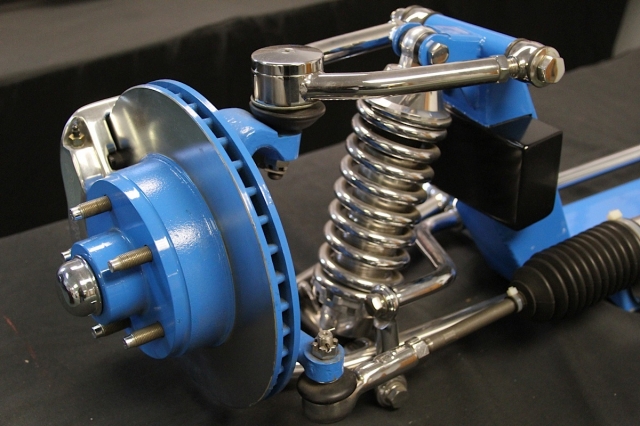

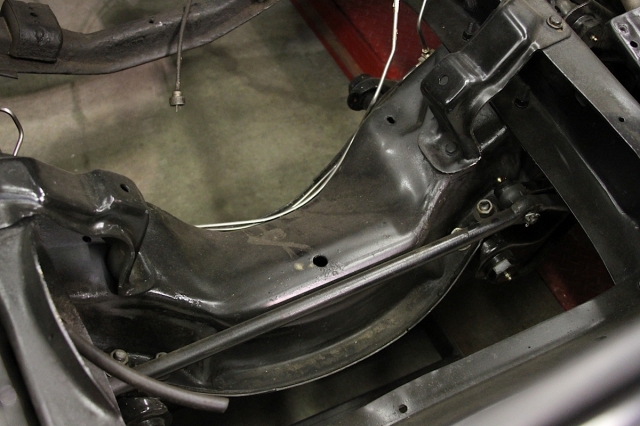

The C-10 line of suspension is much like Heidts’ other offerings with ease of installation, accurate measurement, performance, and durability in mind. The video above features a test rig that Heidts equipped in time for the autocross at the Goodguys PPG Nats in Columbus, Ohio a few weeks back.

The C-10 line of suspension is much like Heidts’ other offerings with ease of installation, accurate measurement, performance, and durability in mind. The video above features a test rig that Heidts equipped in time for the autocross at the Goodguys PPG Nats in Columbus, Ohio a few weeks back.

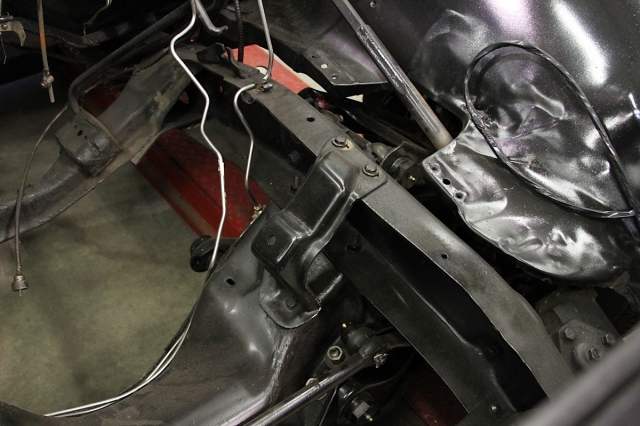

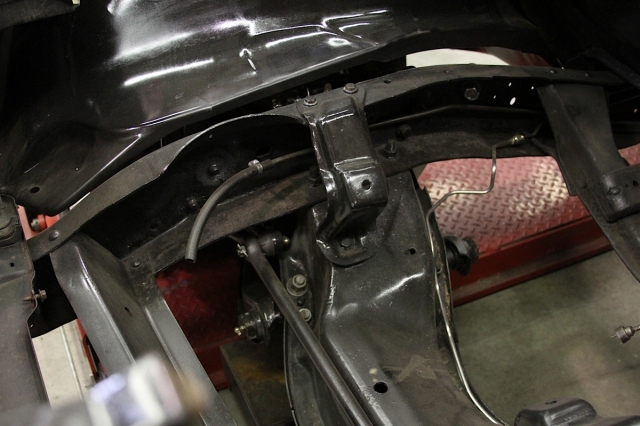

By simply removing the factory control arms and crossmembers, Heidts is able to install its Superide II IFS with ease and have it sit flush due to the company’s meticulous dimension analysis. On top of that, in case you ever want to swap out suspension on to a new ride, the bolt on fasteners for this front suspension make project swaps a breeze!

We can’t wait and hope to see this new line of suspension systems offered for the classic Advance Design and Task Force lines of Chevy trucks – stay tuned and we’ll keep our fingers crossed.