Let’s face it, all the horsepower and torque in the world doesn’t mean a whole lot if you can’t keep the intricate working parts together — from your block’s main bolts all the way to the third member out back and every facet in between. And Stage 8 Locking Fasteners exists for that very purpose of providing high-end, high-quality fasteners for, well, just about everything.

And here at SEMA, they have the “just about everything” covered.

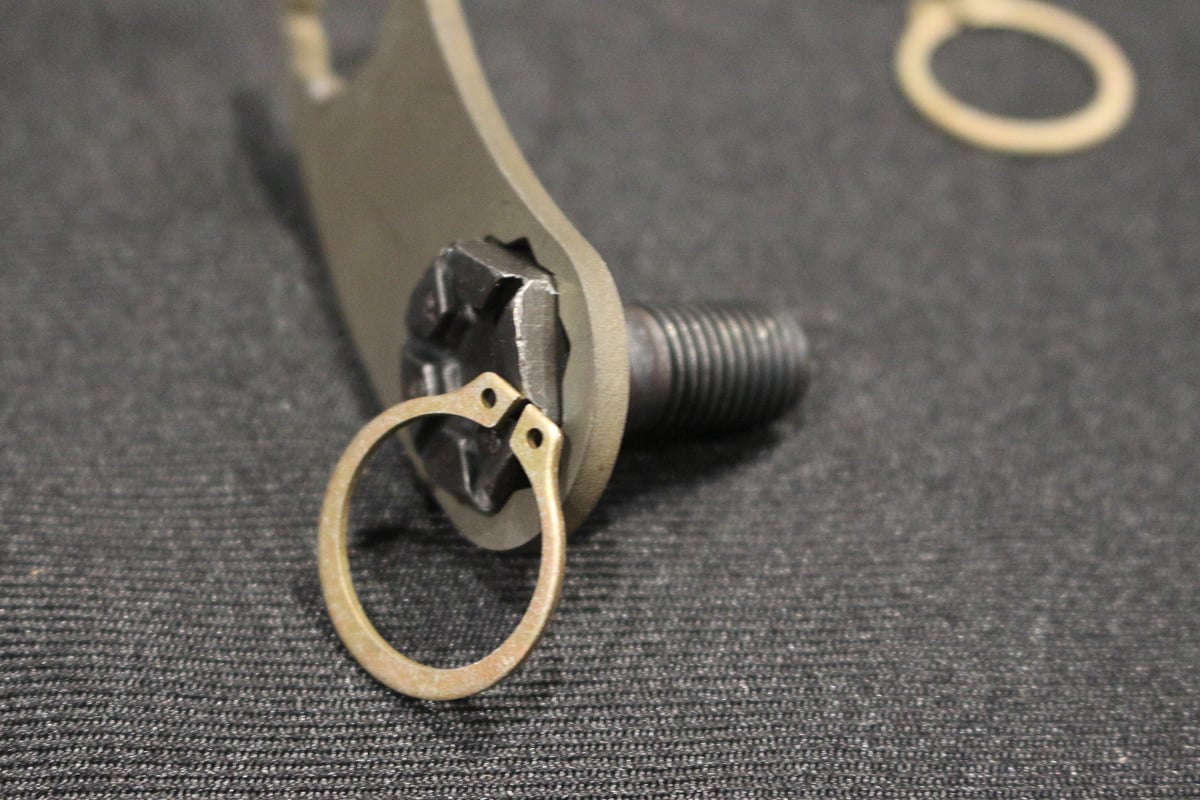

Stage 8’s Glenn Thompson took us for a walkthrough of some of their latest and greatest, beginning with the new fastener design for Ford 9-inch ring and pinion carriers. According to Thompson, one of the industry’s top driveline manufacturers was having difficulty with bolts coming loose on their carriers/housings being used in industrial applications. Stage 8 was called upon to develop a solution, to which they came up with what they call a bridge retainer.

With the bridge retainer design, the bolts can no longer back out – an isue that was being discovered on some industrial applications using Ford 9-inch housings.

The bridge retainer design is simply a grooved or notched bolt head that a snap ring can be installed onto. With this design, which Thompson says he came up with just two weeks prior to the show, a laser-cut plate is placed over the bolt holes, the bolts are installed, and the snap ring is then placed into the notch. With this setup, the bolt can no longer back out, as it’s held firmly in place by the snap ring.

In the fastener business, it’s all about building a better mousetrap, if you will, and Stage 8 did just that with the bridge retainer, providing a solution that goes above and beyond the standard fastener and retaining method.