Needle-bearing roller lifters work great; that is, until the lifter breaks and all those needles scatter. The resulting shrapnel then ends up in the oil system with potential damage throughout the engine.

“The weakpoint of the roller lifter has always been the needle bearings,” explains Nolan Jamora of Isky Racing Cams.

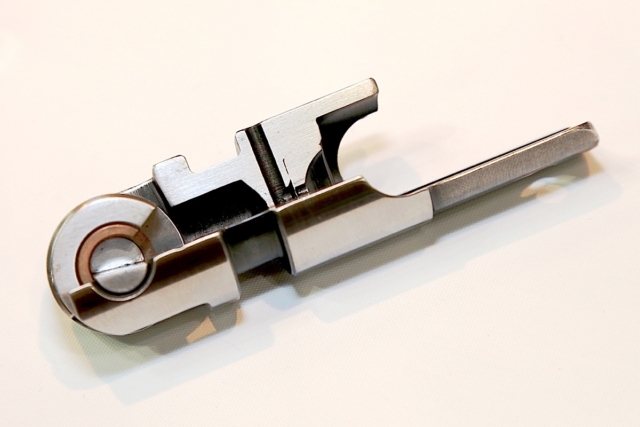

Here’s a closeup of the Isky EZ-Roll lifter. Note the solid bushing that provides a greater surface area to spread the load. In actual operation, there is no mechanical surface contact as the roller will ride on a film of oil.

Countering this potential disaster is the EZ-Roll Lifter from Isky that is needle free. Isky’s proprietary solid bearing can carry a greater load and provides more surface area for load distribution. Two models are available: EZ-RollX and EZ-RollMax. The former is suited for offshore marine and other normally aspirated engines with open spring pressures up to 1,100 pounds and 900 pounds if running nitrous. The EZ-RollMax uses an upgraded solid bearing material and is recommended in .842, .904 and .937-inch applications, especially those with over 400 pounds seat pressure and 1,100 to 1,400 open valve-spring pressure.

Here’s a closeup comparison of the Isky EZ-Roll bearing and a traditional needle bearing. The EZ-Roll will run with engines utilizing oil restrictors.

Isky also offers hydraulic roller lifters with both needle HPx and needle-free HPx-EZ-Roll versions. There is an approximate 30 percent price premium for the needle-free lifters, but in the long run they can save money.

“The solid bearing is much stronger and can last four times longer,” says Jamora. “We had one engine builder with 100 grand in his engine, and a lifter broke. All he had to do was replace the cam and two lifters.”

The EZ-Roll lifters are available for most popular applications, including motorcycles, in standard and lightweight versions, and some are available with pushrod offset.