Automotive batteries and charging systems were once a simple to understand and package. In the good old days of 25 cent-a-gallon gasoline, you had a 45-amp alternator – or perhaps a really lame 25 to 30-amp generator – that only had to keep up with an AM radio or perhaps a Muntz 8-track stereo and very little else besides the vehicle’s ignition system, wipers, heater fan, and lights. If you kept the fan belt nice and tight and most of your accessory switches in the off position, you stood a fighting chance of keeping a six or 12-volt battery charged.

Those Delcotron charging systems of our youth did a marginal job of keeping batteries charged. Start adding accessories and features like electronic engine control to the load and a 65-amp alternator will not keep up.

Times have changed in 60 years of post-war automotive evolution. Today’s cars and trucks – and even our dreamy Chevy classics – have become home away from home.

All the comforts of home are now a huge, added burden for automotive charging systems. Yet, we have neglected to do what it takes to equalize and exceed that new balance of power, and wonder why our batteries tend to roll over and play dead from the strain.

Alternator Need To Know…

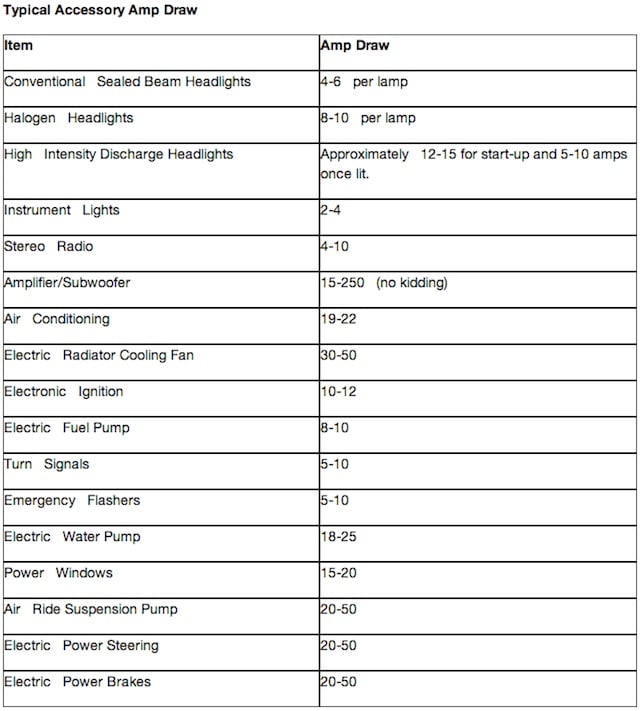

Spend a day on the open highway and you can perceive the battery is adequately charged. However, you’ve had the air conditioning on, powerful sub-woofer blasting, and had been using your GPS and cell phone charger. Halogen and High-Intensity-Discharge headlights take an incredible toll on the battery. Electric power brakes and steering, though intermittent, create a significant amp draw, draining the battery and overloading the system.

When you are planning a charging system, it is suggested you take alternator capacity beyond anticipated needs. It is better to have it and not need it than need it and not have it. Today’s compact space saver alternators fit nearly any accessory package and make a lot of amps. Gone are the outrageously large high-amp alternators of yesterday.

Keeping Up With Demand

Today’s charging system has an overwhelming job to do. Think of your battery and charging system like the humble toilet tank and water supply lines. The tank is your battery and the float valve is the voltage regulator for current flow.

As water is consumed, the float valve fills the tank until the float rises high enough to close the valve. Today’s overwhelming electrical load is like the pesky kid who keeps flushing the toilet over and over again.

Unlike your toilet’s float valve, the voltage regulator isn’t a simple on/off switch, it pulses rapidly on and off to keep battery voltage at a constant 13-14 volts. Where it gets tricky is electrical consumption and keeping the battery charged. If you have a minimum of accessories pulling a battery down, you’re okay.

Think of your battery and charging system like the humble toilet tank and water supply lines.

Carbureted engines need 8 to 9 volts on average to start. Engines with electronic fuel injection need even more. If you’ve converted your classic Nova to electronic fuel injection and are still running an old Delcotron alternator, it just isn’t enough power. Your Nova is going to need at least 100 amps of charging power to keep the battery adequately charged.

The Delco 10Dn externally regulated alternator was common on GM cars though the early 1970s. A mechanical voltage regulator was mounted on the firewall.

The Delco 10DN, 10Si, 12Si

General Motors installed its first alternator – the Delco 10DN – on the 1963 Chevrolet Corvette, which was externally regulated. Other Chevy models swiftly followed. The 10DN was much lighter than the generators it replaced providing steady, consistent amperage at idle. The 10DN was produced into the early 1970s.

GM introduced the internally regulated 10Si series alternator (“Si” stands for “Systems Integrated”) in 1969, which was commonplace in most GM cars and trucks through the mid-1980s. It was available in 37, 42, 55, 61, and 63-amp ratings. The 10Si alternator was followed by the 12Si, which was introduced in 1983.

The 12Si doesn’t look much different than the 10Si except for the high efficiency cooling fan, which was made of plastic. The 12Si was produced in 56, 66, 78, and 94-amp ratings and was a GM mainstay for decades.

GM Alternator Types

- 10DN 1963-72 37-61-amps Externally Regulated

- 10Si 1969-83 37-63-amps (first internally regulated GM alternator)

- 12Si 1983-87 56-94-amp

- 15Si 1982-84 85-105-amp

- 17Si 1986-90 105 amps

- 22/22Si 70-160-amp

- 27Si 1973-85 100-amp

- CS 121 61-74-amp

- CS 130 1986-97 85-105-amp

- CS 130D 1994-up 100-110-amp

- CS 144 1986-95 120-124-amp

- CS 144 1991-up 108-140-amp (Revised version)

Brady Basner of Powermaster Performance in Chicago tells Chevy Hardcore, not enough enthusiasts know how to choose an adequate enough charging system for the job because not enough of us know about accessory load amp draw and what it does to a battery.

Basner suggests first inventorying what you have for electrical accessories and how much amperage each accessory draws and come up with total amps.

When you come up with total amperage requirements, you can then size the alternator capacity to your total known electrical load. Basner stresses your electrical load should never exceed 80-percent of the alternator’s capacity. When you go beyond 80-percent, alternator operating temperature becomes excessive, and burnout is inevitable. You also run the risk of an electrical fire if you haven’t installed circuit protection.

Making A Good Decision

Once you’ve established total expected amp load, you can shop for an alternator and make the right choice. The older GM 10Si and 12Si alternators have limited capacity especially if you’re planning lots of accessories. In stock form, the most you can expect from these old dynamos is 90-100 amps.

The good news is PowerMaster Performance offers 10Si and 12Si high output clones that make as high as 140 amps. These alternators provide an OEM look while kicking amperage up a few notches.

To determine what you need in charging system capacity, first compute what you have for electrical load in amps. A full-charged battery should have 13 to 14 volts.

The main thing you need to think of is available space and alternator size, what type of alternator you want, how you intend to wire the alternator into your electrical system, and the finish desired. If originality isn’t that important to you, step up to 180-200 amps and be ready for just about anything.

Determining Pulley Size

Alternator charge output is also determined by speed which is determined by pulley sizes. The larger the crank pulley and the smaller the alternator pulley, the higher alternator speeds. Alternator speed is not the same as engine speed unless both pulleys are the same size. Alternator RPM is always higher than crankshaft speed by design, in order to keep the battery charged at lower engine speeds.

When you are computing alternator output, Brady Basner of Powermaster Performance suggests examining pulley ratio before doing anything else.

On a street vehicle, Brady says pulley ratio is typically 3:1, which means alternator speed is three times that of crankshaft speed. At idle, 800 rpm crank speed becomes 2,400 rpm at the alternator.

This is Powermaster Performance’s 10Si #47294 natural finish alternator. This is a great retrofit for classic Chevy muscle cars because offers an OEM look and 140 amps.

You want enough alternator rpm to sustain charging. At the same time, you don’t want alternator speed so high you blow the winding in a high rpm explosion.

This is another reason why pulley ratio is so critical. If you’re going to spin your Chevy small-block to 7,500 rpm, that’s 22,500 rpm alternator speed. You want a larger alternator pulley in the interest of getting alternator speed down at high rpm. Instead of a 3:1 ratio, you want something more like 2:1 because most alternators will not tolerate more than 18,000 rpm maximum.

You must also remember not all alternators are driven off the crankshaft. Some are driven off the water pump pulley. This is when you have to calculate water pump to crank pulley ratio to get water pump speed. Then, water pump to alternator pulley ratio, which gives you alternator speed. You want alternator speed high enough to get a healthy charge at idle speed.

Calculating Alternator RPM

Powermaster makes it easy to compute alternator speed. A street vehicle has a 3:1 average pulley ratio according to Powermaster. Take 800 rpm engine speed and multiply by three and you have 2,400 rpm alternator speed. Measure crank pulley and alternator pulley diameter. If the alternator is driven off the water pump pulley, measure the water pump pulley as well (Alternator RPM = Crank Pulley x Engine RPM/Alternator Pulley).

Alternator Cooling

Another issue few of us ever think about is alternator cooling. If you look at the Delco 10Si and 12Si, the most obvious difference is the cooling fan. The 10Si has a more conventional stamped steel fan. The 12Si has a centrifugal molded plastic fan designed to haul more air through the upgraded 12Si. With additional amp capacity comes heat. This is why you must have good air flow through the alternator for heat dissipation.

With the added accessory electrical load comes heat. The more fan and cooling capacity you have the better. Cooling passages fore and aft must be clear. Periodically check your high capacity alternator temperature after a good drive. If it is too hot to touch, air passages are blocked or you don’t have enough amp capacity for the job.

Contrary to popular shop talk, alternator fans draw air in from the back where the rectifier plate is the first component to get cooler air. Air is expelled through the fan in front. Periodically, it’s a good idea to inspect the alternator’s rear inlet for any debris, which can hinder cooling. Also a good idea to check a hot alternator by carefully laying your hand on the case. If it’s too hot to touch, you likely don’t have enough alternator capacity for the job.

Wire Right Sizing

Another very important issue not enough of us think about is charging system wire sizing. Get this too small and you will have a smoking mess. Always err on the side of largeness and play it safe. A battery to alternator charge lead that’s too undersized will cause a voltage drop and wire overheating/melting from the load.

While you’re considering the right alternator capacity for your ride, don’t forget the importance of wire size. When in doubt, go larger – never smaller.

Powermaster Performance suggests the following wire sizing for your mission:

| Amps | 0-4′ | 4-7′ | 7-10′ | 10-13′ | 13-16′ | 16-19’ | 19-22’ | 22-28’ |

| 35-50 | 12 | 12 | 10 | 10 | 10 | 8 | 8 | 8 |

| 50-65 | 10 | 8 | 8 | 6 | 6 | 6 | 6 | 4 |

| 65-85 | 10 | 8 | 8 | 6 | 6 | 4 | 4 | 4 |

| 85-105 | 8 | 8 | 6 | 4 | 4 | 4 | 4 | 2 |

| 105-125 | 6 | 6 | 4 | 4 | 2 | 2 | 2 | 0 |

| 125-150 | 6 | 6 | 4 | 2 | 2 | 2 | 2 | 0 |

| 150-175 | 4 | 4 | 4 | 2 | 2 | 0 | 0 | 0 |

| 175-200 | 4 | 4 | 2 | 2 | 0 | 0 | 0 | 00 |

| Wire Size |

Powermaster Performance also suggests taking a voltmeter and checking output from the alternator. Then, check all points in the electrical system at the sources of amp draw with that accessory turned on. You should see no more than a 0.5 volt drop between the alternator and battery.

The Alternator Marketplace

There was a day when the only place you could expect to find new and rebuilt alternators was your local auto parts store. Some of us were gutsy enough to rebuild them ourselves. And honestly AutoZone, Pep Boys, O’Reilly’s, Advanced Auto Parts, and a host of other national and regional chains stock both new and remanufactured alternators for run of the mill applications. Some offer a lifetime guarantee. This works if you’re building a classic Chevelle or Impala stocker and won’t have a host of accessories on board.

Summit Racing Equipment stocks virtually every kind of GM alternator imaginable and from a variety of manufacturers in stock and high output amp ratings. Summit also markets its own brand of GM alternators along with Powermaster, Tuff Stuff, and others. A trip to Summit’s website will yield plenty of choices once you’ve narrowed down amp rating, size, and style.

Summit Racing Equipment stocks virtually every kind of GM alternator imaginable and from a variety of manufacturers in stock and high output amp ratings. Summit also markets its own brand of GM alternators along with Powermaster, Tuff Stuff, and others. A trip to Summit’s website will yield plenty of choices once you’ve narrowed down amp rating, size, and style.

Tuff Stuff Performance has a broad product line that also includes quite an array of GM alternators ranging from the original 10Dn to the CS130 and CS144 in amp ratings ranging from 80 to 225 amps. Tuff Performance tells us you may opt for the original 10Dn for an OEM look in amp ratings ranging from 80 to 140 amps. This enables you to install the 10Dn on your box stock Chevelle, Camaro, or Nova at 140 amps and few will know the difference.

Tuff Stuff alternators are all new inside with spike-resistant diodes and new copper windings. Cases are available in natural or polished aluminum. Because these are externally regulated, Tuff Stuff Performance includes the wiring harness. Voltage regulator is not included, but it is suggested you opt for a solid state regulator for best results and predictable charging.

Meet PowerGEN from Powermaster Performance. PowerGEN is a high output alternator that looks like a generator. It produces 75 amps with whopping 60 amps at idle speed.

My Alternator Thinks It’s A Generator

If you own an older classic Chevy with a generator and would like to outfit the car with accessories a generator couldn’t hope to handle, Powermaster Performance’s PowerGEN alternators are the perfect drop-in replacement. PowerGEN is an alternator that looks like a generator. There are four pulley belt widths available in black and chrome — 3/8-, 1/2-, 5/8-, and 3/4-inch. PowerGEN is available for 1939 through ’57 Chevrolet.

Tuff Stuff alternators are available in natural or polished aluminum finishes in amp ratings ranging from 80 to 140 amps. It is suggested you go with 140 amps regardless of what you have for accessories, which means never having to worry should you add accessories later on.

Have You Checked Belt Tension?

Belt condition and tension cause more charging system heartache than anything else. Although it may seem like an alternator doesn’t put much load on an engine, it does and it places a great burden on your V-belt. If you suspect, but can’t prove there’s belt slippage and your battery isn’t maintaining a healthy charge, check the alternator pulley groove for black dust and discoloration.

How does the belt fit? Is the belt too deep in the pulley groove or too high? Your V-belt must fit the groove dead perfect meaning the belt’s back is flush with the top of your pulley groove. Take a socket wrench and try to turn the alternator pulley clockwise. If you can turn the pulley, the belt isn’t tight enough. If the pulley turns but doesn’t turn the engine’s crankshaft, it isn’t tight enough.

Summit Racing Equipment offers a nice variety of house brand GM alternators yielding extraordinary quality and power output but at more affordable prices. If you’re on a tight budget and need charging capacity and good looks, check out Summit’s website.

The Heart of The Matter — Your Battery

We’ve talked a lot about alternator and wiring capacity. But keeping the lights on and engine running is primarily up to that toilet tank we were talking about earlier — the battery.

There are lead-acid storage batteries and there are gel-cell. We’ve been using lead-acid storage batteries in automobiles for more than a century. We’ve come to know all of their quirks and learned how to improve the design, but the basic fundamentals haven’t changed much. The marketplace is generous with all kinds of lead-acid storage batteries for cars and trucks. And there are plenty of familiar brand names — DieHard, AC/Delco, EverStart, Durastart, and a host of others.

There are basically three automobile battery manufacturers that make all these brand names — Johnson Controls, Exide, and Delphi that make batteries for a wide variety of brand names. In the end, it isn’t so much about the brand or manufacturer you choose, but what the battery consists of.

Lead-acid batteries remain the industry standard due to cost and ease of maintenance. You want the largest battery that will fit your tray along with the highest cold cranking amps.

Bigger Is Better

When you’re shopping for a battery, you want the largest battery you can fit in the tray with the highest cold cranking amps (CCA). This is the area where it’s definitely safe to error on the side of “too much” battery as your application can only draw what it needs. Battery size is known as “Group Size” along with specific applications such as Chevrolet with either top or side terminals.

A battery’s cold cranking amps is a measure of how the battery will perform in extreme cold — zero degrees F to be exact. Cranking amps or “CA” is a measure of what the battery will do at 32 degrees F. Reserve capacity is how much time you can expect your battery to provide power should the alternator fail.

Never choose a battery on the cheap. You get what you pay for. The higher the CCA and CA, the more you’re going to spend. However, you get greater starting power in the cold and longer warranty. CCA and CA are rooted in how much the battery offers in terms of lead composition plates in each cell. In other words, the more plates you have in each cell the higher the CCA and CA not to mention reserve capacity. And, when you deep cycle charge (trickle charge) a battery over a period of 8-12 hours, you will have more battery when it counts when you’re alone in the cold sitting behind the wheel of a Chevy with morning sickness.

Alternative Battery Technology

An alternative to the lead-acid battery is the Absorbed Glass Mat (AGM) battery made by Optima Battery. Optima says the AGM design battery keeps the electrolyte in safe suspension while keeping it in constant contact with the lead plates. You get more lead plate and greater cranking power with the sealed AGM battery from Optima.

There is also the SpiralCell high-performance battery from Optima, which takes the AGM cell battery design to new levels. “At the heart of every OPTIMA battery is a series of individual spiral-wound cells comprised of two pure (99.99%) lead plates coated in a precise coating of lead oxide. One coated plate is positive and the other is negative,” Optima tells Chevy Hard Core, “Each lead plate is manufactured as a continuous cast strip that maintains critical thickness tolerances. The two plates get a proprietary separator (this key component is actually made of a micro-fiberglass blend that feels like fine cotton) that performs two critical functions. It keep the two plates from touching and holds the electrolyte in a uniform suspension.”

Optima Batteries offers the toughest batteries around thanks to AGM and SpiralCell technology. If you have a late model or classic Chevy you don't drive very often, the Optima high-performance, low maintenance battery is for you. These batteries are happy just sitting between outings. By the same token, they do require special treatment charging available from Optima if the vehicle is going to sit for months. The Optima costs more than a conventional lead-acid battery, however, they have a long lifespan and require very little attention.

Optima Batteries also offers a deep-cycle battery known as the SLI Deep-Cycle designed specifically for vehicles that sit for extended periods of time between drives. There are three types of SLI Deep Cycle batteries designed for specific types of applications. The REDTOP is the one most of us are familiar with for occasional drivers, which delivers faster starts under extreme conditions. The REDTOP is fully capable of maintaining your classic Chevy’s operation during idle and low speed conditions where the alternator isn’t quite keeping up with demand. The YELLOWTOP is for heavy cycling and fast recharging. The BLUETOP is a marine battery for RV and marine use.

Now That You Know

Once you understand the dynamics of a charging system versus accessory load, it becomes easier to understand how to package and maintain one of your Bow-Tie’s most important safety systems. Key to reliability and performance is to always be prepared regardless of how often you drive your Chevy. You want an enjoyable ride you could start up and drive anywhere at any time.