Rodney Klein of Amarillo, Texas has had a love affair with Mopar for the last 37 years. He bought his first car, a 1971 340ci, four-speed ‘Cuda when he was 17 years old. The car came from New York and had rust issues in the front subframe. Even though it was a blast to drive, he ended up parting out the car in 1983. He pulled the 340ci engine and put it into a 1974 Duster, driving it for a year or so, before selling it to join the US Navy in 1984.

Rodney Klein of Amarillo, Texas has had a love affair with Mopar for the last 37 years. He bought his first car, a 1971 340ci, four-speed ‘Cuda when he was 17 years old. The car came from New York and had rust issues in the front subframe. Even though it was a blast to drive, he ended up parting out the car in 1983. He pulled the 340ci engine and put it into a 1974 Duster, driving it for a year or so, before selling it to join the US Navy in 1984.

After boot camp, he bought a 1970 Challenger that had a transplanted 440ci and a 6bbl which he owned for a couple of years. During that time, he rebuilt the engine and decided he wanted a 1969 Dart to put it in. A friend knew of a 1969 383-s fastback Barracuda (1of 331)which Rod purchased for 800 bucks. He kept the 383-s for over 25 years before he sold it to build his dream: A 1971 Barracuda.

The ‘Cuda was originally listed as a “GT2,” Tunisian Tan with a white top and is a “VO2,” a two-tone car.

He started on the Barracuda about two years ago. It was originally a 318ci base model, with an automatic transmission and A/C. The ‘Cuda was listed as a “GT2,” Tunisian Tan (only 1-2 percent of Barracudas and Challengers were GT2), and is a “VO2,” a two-tone car. This one had a white top. As rare as this is, Rod doesn’t like the color combination and plans on painting it gloss black.

Although it was a Texas panhandle car, it had a fair share of rust. Rod ended up replacing both quarter panels, one outer wheel house, trunk floor, trunk floor extensions, one rear floor board, deck filler panel, gas tank braces, trunk gutters, lower front windshield corners, and many patches in the floor. The speaker tray, windshield frame, hood hinge area, inner fender area near the battery were repaired as well. There is nearly a year of work getting the car to be rust free. All the metal work was done by Rod for the first time.

Before and after! A lot of work went into the "after" photo...and even more to come.

Rod decided to low-buck some of the build. He didn’t want to spend a lot of money to buy a rotisserie for a one-time use, so he built one out of wood – he spent around 25 bucks on wood, bolts, screws, and glue. A friend gave him a few old plywood doors so he could roll the car on its side. Rod and his older son were able to roll the Barracuda up on its side without too much trouble and the car would still fit into his garage. It made it so much easier cleaning the bottom, finish welding, and eventually painting.

The 'Cuda wasn't exactly a rust-free Texas panhandle car...it required a lot of work.

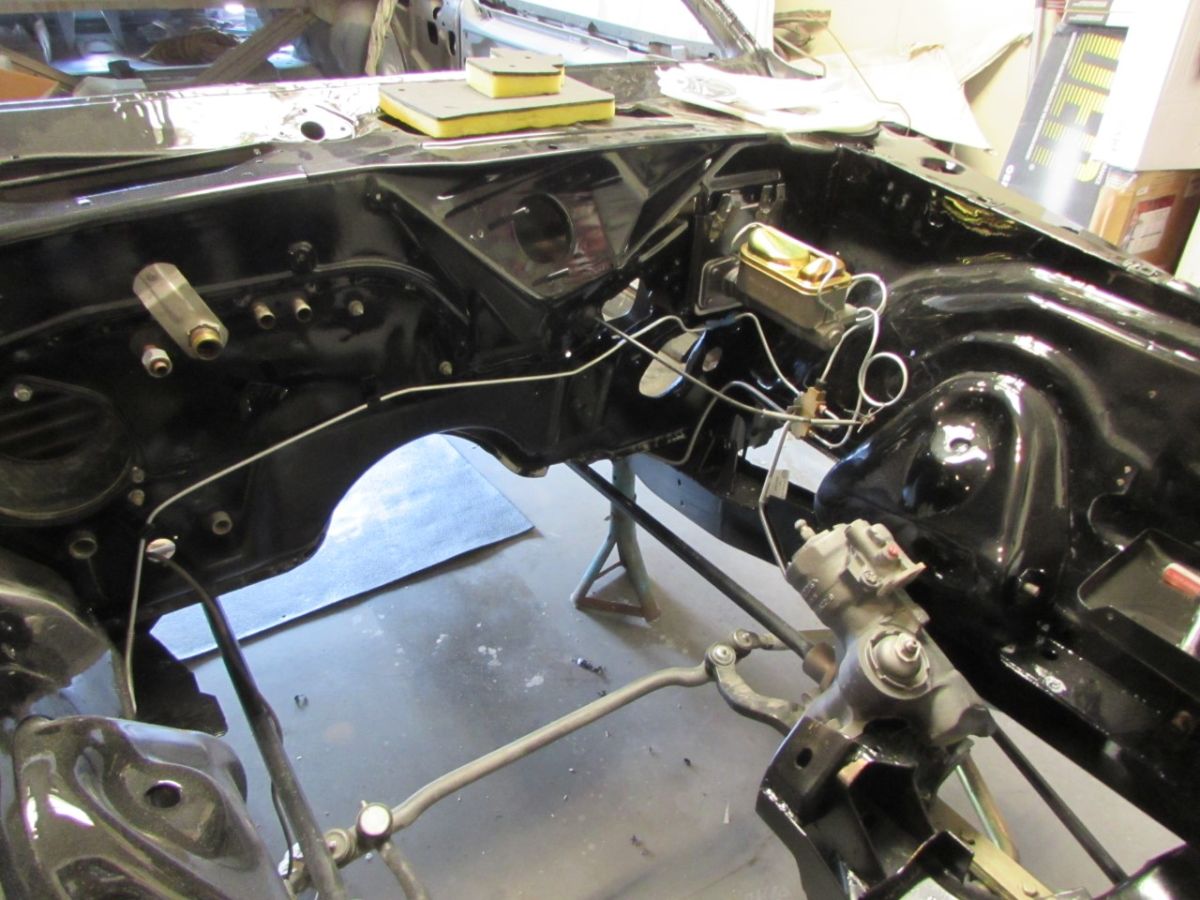

Some friends asked why not start with a better Cuda and not do all the work. Rod stated he wanted to build the car without worrying about originality. He wants to drive the wheels off it! Part of the upgrades include a US Car Tools frame – stiffening kit, four-wheel disc brakes, 4-speed conversion, 1.03 PST torsion bars, QA1 upper control arms, boxed lower control arms, C-body tie-rod ends, and bigger front sway bar. The power steering box was rebuilt by Firm Feel. The 8.75 rearend was stuffed with a 3.54 sure-grip. Custom brackets were built to hold a Sanfield style A/C compressor. Another modification was the installation of a Borgeson U-joint to replace the factory steering coupler.

Getting there slowly. It's taken a few years so far.

Modifications to the dash and wiring were also done –Rod installed a voltmeter to replace the fire-prone ammeter, modified the wiring harness to add Rally gauges, upgraded the clock to quartz movement, and installed a new tach motherboard. He’d planned on redoing the dash pad, but ended up recognizing that he didn’t have the equipment or expertise to do it himself. Because E-bodies have a ton of plastic, Rod learned how to repair ABS plastic pieces, of which nearly every piece needed some level of repair. These parts can get really expensive, so being able to repair them helped a lot.

Left: The dash has been rebuilt with new gauges. Right: Back into the car.

The original intent for the engine was to buy a solid 5.9-liter Magnum and add some EQ heads. A tear down revealed a destroyed crank thrust-bearing surface so the build morphed into a 408ci stroker. The engine was bored .030 over and stuffed with KB pistons. A local machine shop internally balanced the MP crank and purchased Eagle rods. A reground Magnum cam, stock roller lifters, and roller rockers completed the build. Future plans call for an EFI, but he currently runs an LD340 and a Holley 780 vacuum secondary for induction. A set of shorty headers was chosen primarily for ease of installation (and cost). An A833 with the requisite pistol grip shifter was a must, although a Passion five-speed might happen at a later date. A Centerforce clutch was installed.

Left: Bare block awaiting finishing. Right: The assembled engine fits snugly in its compartment.

Immediate future plans include installing the dash and double checking all mechanicals. Hopefully, by the end of next summer, Rod will have completed final bodywork and painted the exterior of the car TX9 – gloss black. The wheels have not yet been determined. Seventeen inch Torque Thrust wheels are still on his brain, but he’s leaning toward 17-inch Rallye wheels, although stock 15-inch Rallyes are still possible. Plans also include aftermarket or late-model bucket seats that have the same feel as the originals. Rod might consider some graphic on the rear quarters in the future, possibly the 1970 hockey stripes.

Left: The refinished engine compartment resplendent in gloss black. Right: Starting to look like a Barracuda again.

People ask Rod if he’s going to sell the car when it’s done. To that he replies, “I kept my ‘69 for 25 years. I guess my wife can sell my ‘71 when I am gone.”

What do you think about Rod’s project car? Let us know in the comments below and send us an email if you have a project of your own.